Low slope roof penetrations can be a source of problems if not done correctly.

Pipe, vent, and conduit penetrations through low slope roof assemblies can cause problems for an otherwise tight membrane, insulation, and deck design. With many intermediate layers in roof assemblies, such as a vapor retarder and cover board, there are opportunities for things not to be done correctly somewhere in the assembly. It gets even more complex when we consider that in order to use a vapor retarder, there might be an additional cementitious board above a steel deck.

This article provides an overview and is intended to be used as general guidance only. For specifics refer to the GAF Single-Ply Pro Field Guide and, when using the GAF SA Vapor Retarder also review the Guide to Vapor Retarder Design in Low-slope Roof Systems. Let's look at each part of the roof assembly, starting at the bottom:

Deck Level:

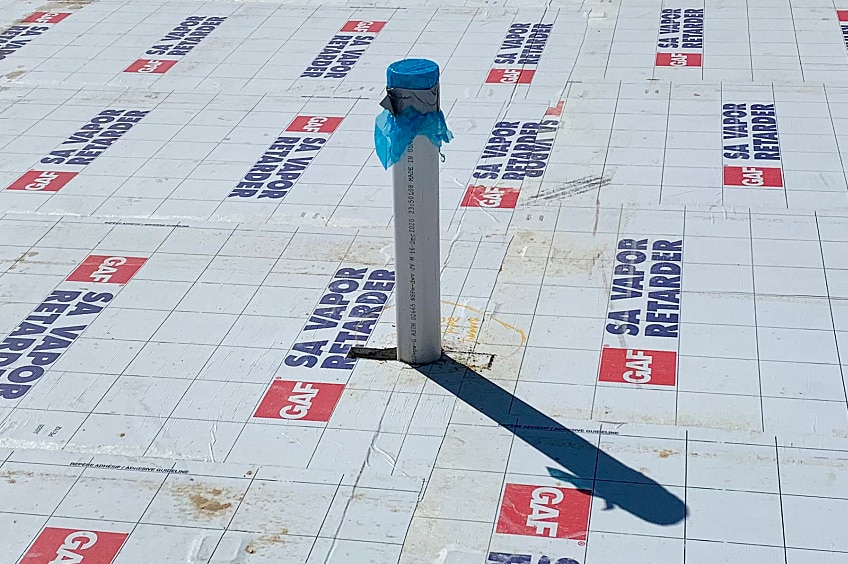

If a separate vapor retarder is being installed, this is where it will be placed; either direct to deck or onto a cementitious board or HD polyiso. A self-adhered vapor retarder installed at the deck significantly reduces the diffusion of moisture and blocks the movement of interior humid air up into the roof assembly. Any penetration needs to be flashed carefully to prevent interior air from bypassing the vapor retarder. Best practice is to field fabricate a collar out of the vapor retarder and wrap it around the pipe as shown here:

A target sheet is then placed over the collar and any remaining gaps can be sealed with GAF Flexseal™ Caulk Grade Sealant. The completed flashing is shown below:

Important – as shown in the schematic above, sometimes the gap around a deck penetration is larger than can properly support a flashing. When this is the case, be sure to fill the gap with foam, using a foam pack, to act as a support and to block air flow. This also helps further reduce the risk of air infiltration from the building interior up into the roof assembly.

Insulation / Coverboards

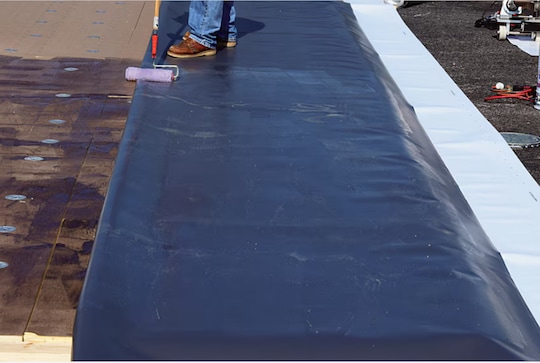

It is not unusual to see gaps around penetrations through insulation and coverboards. These gaps don't just act as thermal bridges but they also allow air to freely move up into the roof assembly. This is especially true for mechanically attached membranes during wind events. Best practice is to fill the gaps with foam as shown here:

By filling any gaps between penetrations and insulation and coverboards, the risk of interior humid air reaching the underside of the membrane is minimized. This in turn reduces the risk of condensation issues in cold climates.

Important - Always make sure that the two layers of insulation have staggered and offset joints. If coverboard is used, also ensure that its joints are staggered and offset from those of the topmost layer of insulation. In this way, air movement up through the assembly can be minimized.

Single-Ply Roof Membrane

Penetrations through single-ply roof membranes can be sealed with field fabricated flashings or prefabricated accessories. While field fabrication can be successful, the risks of inconsistency and errors can be reduced by using one of a range of prefabricated accessories designed to help flash in penetrations. The GAF TPO Accessories are a good place to start, allowing many situations to be addressed such as inside and outside corners, penetrations, vents, and skylights.

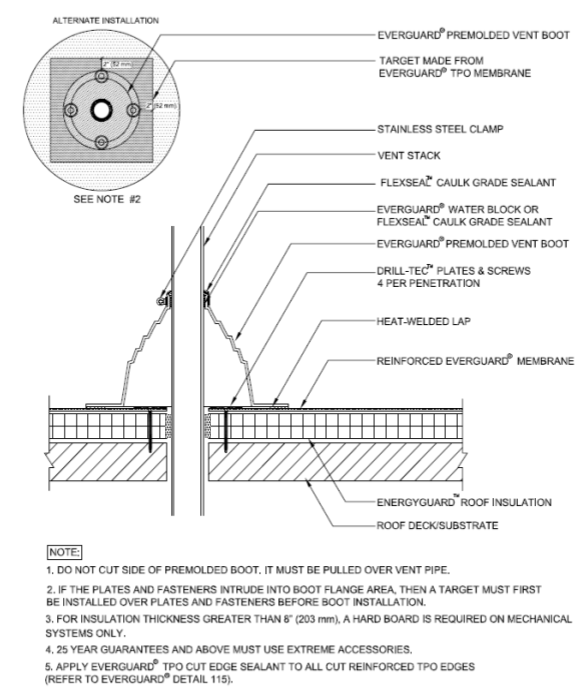

Keeping with the example of a pipe penetration, the following shows how to properly install a pre-molded pipe boot:

Note that for a mechanically attached membrane, an additional four fasteners should be used around the penetration. A target patch can be required if the four fasteners need to be spaced further away from the penetration to ensure a good anchorage. However, the GAF vent boot is designed with a large 6 inch flange that often eliminates the need for a target patch.

Important – as has been stressed before, do a final check that gaps around the penetration are sealed with foam, before doing this final installation. In many cases, condensation issues first occur around a penetration due to the ability of interior air to bypass the insulation layers and reach the underside of the roof membrane. Note that GAF offers custom cylindrical pipe boots which can be custom fit to the penetration to eliminate any air on the inside of the accessory which can help reduce condensation.

Important Considerations

The purpose of this article is to provide some background information and design considerations for addressing roof penetrations. GAF manufactures and sells roof materials but is not responsible for building design and construction. Design responsibility remains with the architect, engineer, roofing contractor, or owner. This information should not be construed as being all-inclusive, nor should it be considered as a substitute for good application practices. Please consult your design professional for more information.