Roof vents form the base of your attic ventilation system. They let your attic breathe—and they help protect your roof system from damaging heat and moisture.

Here's how two important types of roof vents work and what benefits they can bring your house.

What Products Do I Need for an Effective Attic Ventilation System?

An attic ventilation system consists of intake vents and exhaust vents. Together, these products can be used to create a balanced attic ventilation system that helps to reduce attic temperature and excess moisture.

Intake vents, located at or near the bottom of your roof, are a very important part of your attic ventilation system. These vents allow fresh air from outside into the attic. If there's no air coming in, then no air can flow out, reducing the effectiveness of the attic ventilation system and potentially causing roof system degradation.

This air current continually flows through the attic and then back outside through exhaust vents positioned at or near the top of your roof. The vents help protect the roof system from the inside out. It's important that the amount of exhaust ventilation at or near the ridge does not exceed the intake air ventilation at or near the soffit.

Types of Intake Vents

There are two types of intake vents: soffit vents and rooftop intake vents. Most homes have soffit vents if they are constructed with roof overhangs or eaves. Because the soffit is typically located at the lowest point of the roof, it's in the perfect spot for fresh air to enter the attic. Soffit vents come in various styles, including individual vents, continuous strips, and ventilated soffit panels.

Homes with limited or no soffits can use rooftop intake vents, which do not require homeowners to build expensive new soffits or alter existing ones.

Choosing Exhaust Vents for Your Attic Ventilation System

Exhaust ventilation is most efficient when it's installed at or near the highest point of your roof where hot, humid air can easily escape. Exhaust vents are divided into three common categories: static, powered, and mechanical.

1. Static Exhaust Vents

Since they make use of the natural flow of air as hot air rises, static exhaust vents do not require electricity.

There are three types of static exhaust vents:

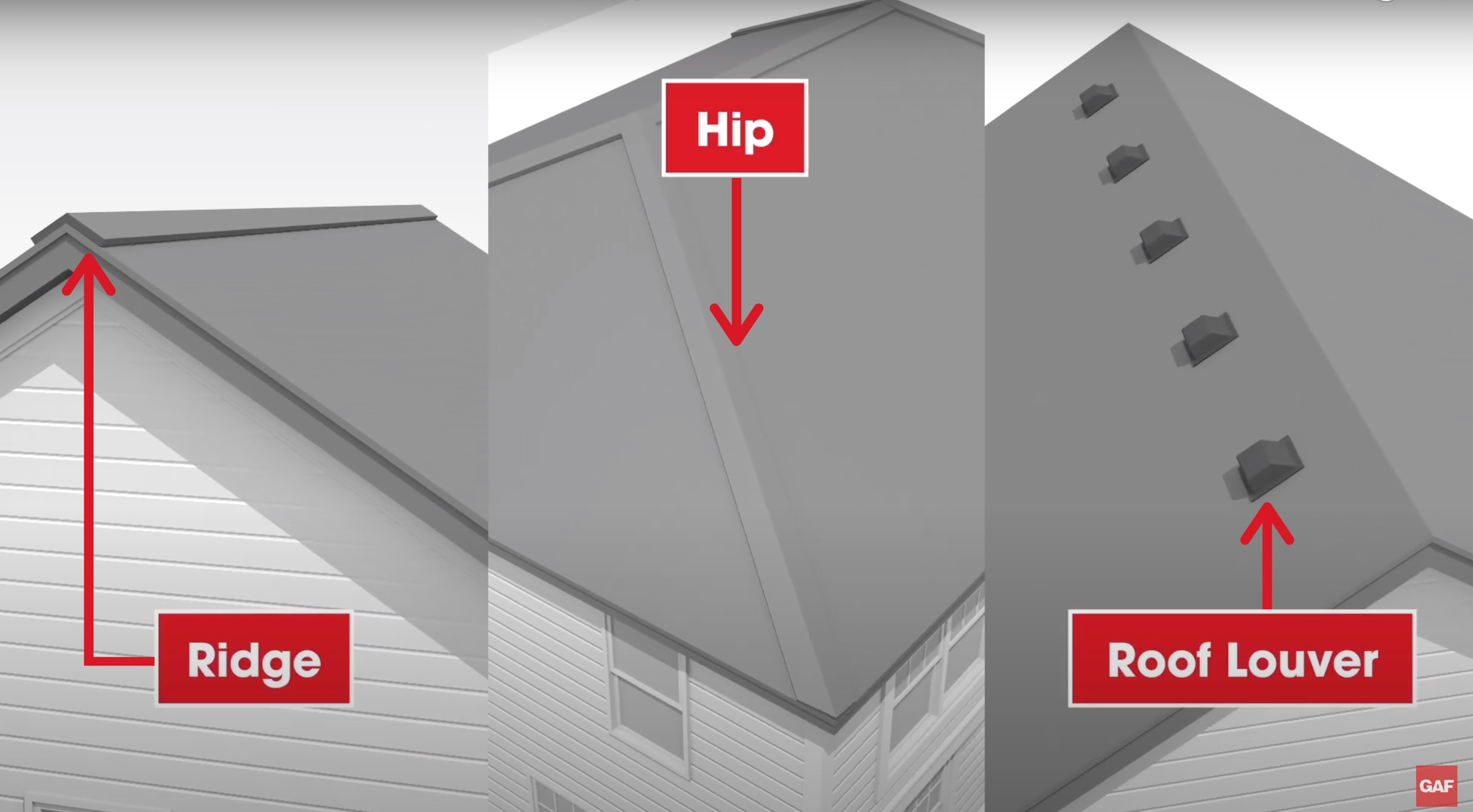

Ridge vents: These are installed on most homes, since this type of exhaust vent is effective and fairly easy to install at the highest point of the roof: the ridge or peak. It's the ideal location to allow hot air to escape the attic. Ridge vents also blend in with the finished roof thanks to their low profile. They are covered by ridge cap shingles.

Hip vents: Hip vents are similar to ridge vents in both design and function. They help ventilate homes with hip roof designs that have very limited or no ridge area. To provide a uniform appearance, the hip vents themselves are typically installed along the entire length of the hip, while the air slots underneath the hip vents are located only at the top portion of the hip. Depending on the design of your roof, hip vents can also be combined with ridge vents to provide the amount of exhaust your attic needs.

Roof louvers: Also known as box vents, roof louvers offer another exhaust vent option for modern roof designs, hip roofs, smaller roof areas, and those with limited or no ridge line. In order to achieve the proper amount of exhaust ventilation, roof louvers usually require the installation of multiple vents due to their small size. However, the louvers can be installed on the back portion of the roof for a streamlined appearance. They can be installed on both existing or new roofs.

2. Powered Exhaust Vents

Powered exhaust vents help remove a large volume of warm, humid air from the attic. Powered by electric, solar, or a combination of both, often referred to as dual-powered or hybrid, these vents have different cubic feet per minute (CFM) airflow ratings: the higher the CFM airflow, the faster the vent exhausts air out of the attic. Powered vents typically include thermostat control with some models available with an optional humidistat/thermostat control.

There are two common types of powered exhaust vents:

Roof-mounted: In electric, solar or dual-powered options, these exhaust vents are installed over the openings in the roof deck.

Gable-mounted: This type of exhaust vent can be easily installed from inside the attic, which helps avoid roof penetration.

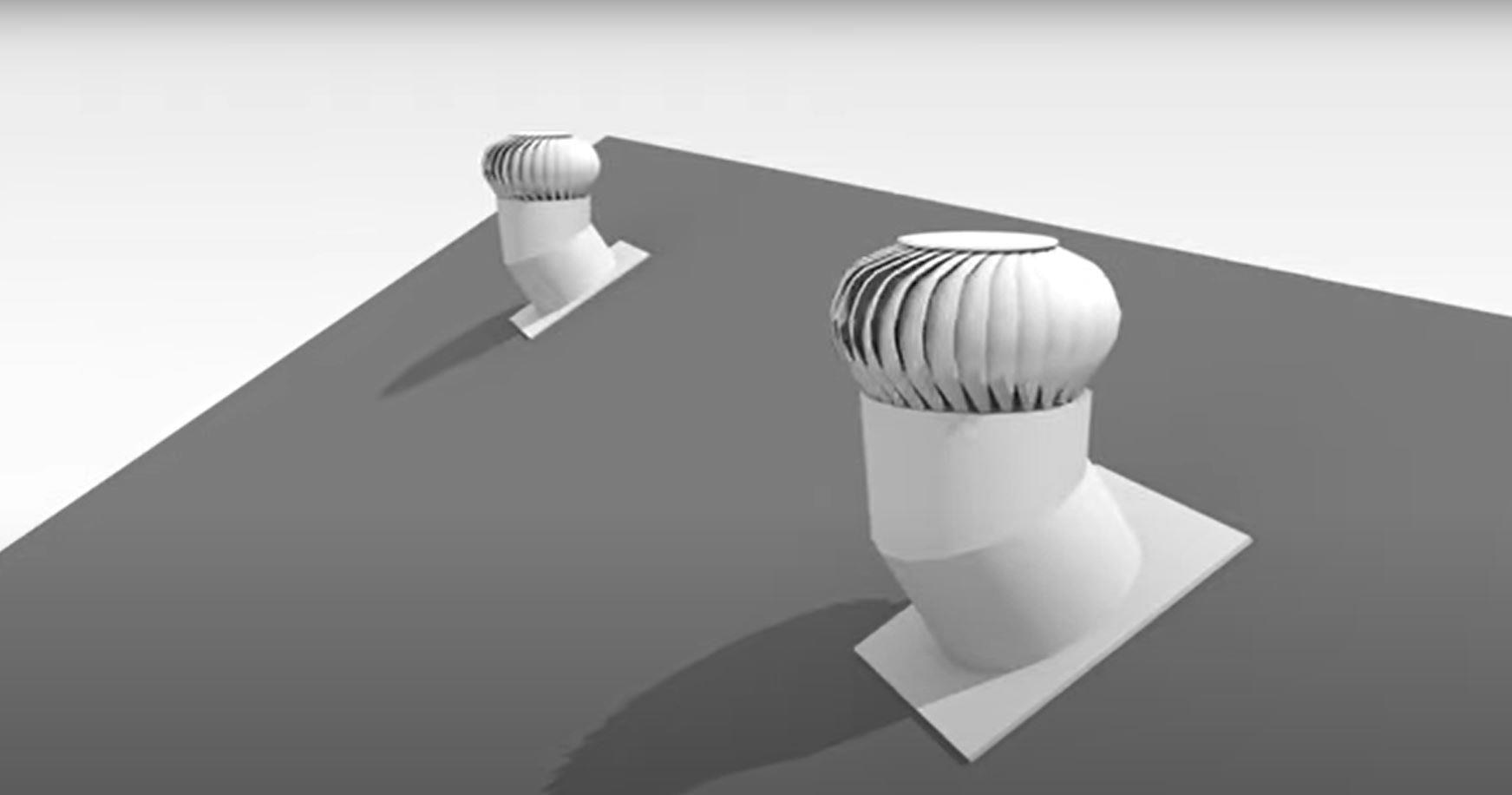

3. Mechanical Exhaust Vents

Mechanical exhaust vents such as wind turbines harness the power of the wind to help remove excess heat and moisture from the attic. With enough wind, the turbine spins and pulls heat and moisture from the attic. Turbines sit higher above the roof surface, so they stand out more than other exhaust options, but they move air effectively. When there's no wind, their function is similar to that of a static exhaust vent.

Which Types of Roof Vents are Best for my Home?

Every home is different. The best vents for your roof will depend on your home's architectural style, the design of your roof, and your local climate. It's important not to mix different types of exhaust vents in the same attic space, which can prevent proper airflow through the space.

A qualified roofing professional can implement a balanced attic ventilation system of intake and exhaust vents that will help reduce excess heat and moisture from your attic. To help calculate your attic's ventilation needs, click here or contact a contractor certified by GAF* near you.

* Contractors enrolled in GAF certification programs are not employees or agents of GAF, and GAF does not control or otherwise supervise these independent businesses. Contractors may receive benefits, such as loyalty rewards points and discounts on marketing tools from GAF for participating in the program and offering GAF enhanced warranties, which require the use of a minimum amount of GAF products.