Como contratista de techado comercial, eres responsable de elegir los materiales adecuados para cada trabajo. But with so many options available, making a decision can be difficult.

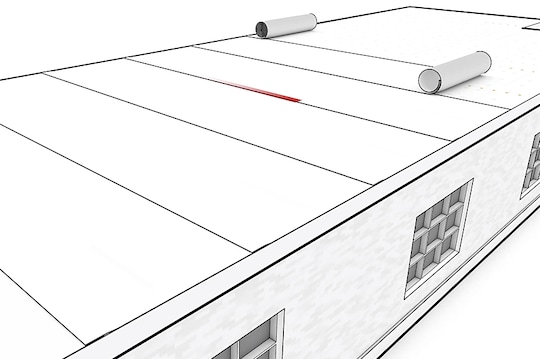

Increasingly, industry professionals have been turning to silicone roof coatings for their strength and durability. Estos revestimientos pueden ayudar a prolongar la vida útil de un techo estructuralmente sólido y, potencialmente, ahorrar tiempo y dinero a los propietarios al retrasar la renovación total del techo. Además, sus propiedades restaurativas funcionan a la perfección con la mayoría de los sistemas de techos comerciales, como los techos EPDM, multimembrana y de betún y metal.

What Are Silicone Roof Coatings?

Silicone coatings are high-performance, waterproof protective roof coatings. La aplicación de este revestimiento a un techo estructuralmente sólido favorece la prolongación de la vida útil del techo existente. Al ser inorgánica, la silicona mantiene sus propiedades en condiciones meteorológicas adversas. It's also flexible and can absorb most normal roof movement to help avoid cracking and losing its protective features.

Benefits of Silicone Roof Coatings

In addition to flexibility and extending the life of the existing roof, silicone coatings offer several other benefits. Laura Soder, senior product manager for liquids and coatings at GAF, explains that GAF silicone coatings are designed to help protect against leaks and provide related advantages.

UV Ray Protection

The major benefit of silicone coatings is ultraviolet (UV) ray protection. "La silicona de GAF está formulada con dióxido de titanio, que aporta una excepcional estabilidad frente a los rayos UV y una alta reflectancia solar", sostiene. This UV protection can help lower roof top temperatures, which may translate into more efficient operation of roof top units.

Económico

Silicone coatings are cost-effective solutions that can help delay the cost of materials and labor needed to replace the entire roof. They work great with most commercial roofs and pair exceptionally well with metal roofs.

Restores and Helps Extend the Life of the Existing Roof

Soder notes that silicone coatings adhere well to metal roofs, making them an excellent way to extend the service life of metal roofs. Antes de la aplicación, cepilla el óxido más ligero o aplica un tratamiento localizado al óxido más pesado. "There are a lot of metal roofs out there, and for those that are structurally sound and require only moderate restoration, you can easily add years to the roof's life by coating them with silicone," she says.

Moisture-Resistant

Silicone coatings are also known for their moisture-resistant capabilities. Since silicone is inorganic, it resists degradation in areas that pond water, making it an ideal choice in areas that experience rain or snow.

Works in Hot and Cold Weather

Silicone has a wide temperature application range. Como es un material que no contiene agua, permite aplicarlo en temperaturas más bajas que el acrílico y otros revestimientos para techos. Aporta una capa de impermeabilización monolítica y sin imperfecciones sobre los techos de metal existentes. Silicone will also flex with metal in cold and hot weather.

How Silicone Compares to Elastomeric Coatings

Compared to acrylic and other elastomeric roof coatings, silicone has some advantages.

Acrylics are water-based protective coatings with UV resistance -but they shouldn't be installed where there is ponding water, as they can break down and start delaminating. Silicone is a moisture-cure material, meaning it reacts with moisture in the air and cures to a finished film.

Soder explains that both materials are flexible and appropriate for use over metal. Pero si hay agua estancada, el acrílico no es la mejor opción. "Si bien la silicona es más costosa, suele desgastarse a un ritmo mucho más lento que otros revestimientos", afirma. That said, one of silicone's drawbacks compared to other elastomeric roof coatings is that it's slippery when wet.

Navigating Installation and Application

While silicone coatings can help extend the life of an existing roof, Soder notes it's best to install the coating before the end of the existing membrane's service life.

Since leaks tend to happen at roof seams, add silicone sealant to these areas. Los selladores se formulan de forma diferente a los revestimientos: utilizan distintos polímeros de silicona que les otorga una consistencia más densa y una estructura más duradera. Los selladores de silicona están formulados para zonas de gran exigencia y ayudan a absorber el movimiento en puntos críticos del techo. They work hand in hand with a silicone coating to protect the roof.

Before you apply any coating, ensure the roof is clean, dry, and sound. "Limpio significa sin contaminantes, polvo, aceites, hojas ni otros residuos", dice Soder. You can use GAF Cleaning Concentrate to power wash your roof.

Since silicone is moisture-cure, the roof needs to be dry before applying. Aplicar el revestimiento sobre una superficie húmeda puede afectar la adherencia; uno de los principales errores al instalar. You want the coating to start the curing process from moisture in the air, not from moisture on the roof.

How to Apply Silicone Coatings

Applying a silicone roof coating involves five steps:

- Clean any debris off the roof and test that the coating will properly adhere to the surface.

- Ensure the roof is in sound condition. Repair broken sheet metal, and replace missing or damaged fasteners.

- Treat all seams and fasteners with silicone sealant like GAF Silicone Mastic. Apply it at 60 mils or 1/16-inch wet thickness with a brush.

- Use the same sealant on any curbs, penetrations, and drains.

- Finally, apply the silicone roof coating to the entire roof. Some coatings, like GAF Unisil Silicone, require two coats, while others such as the GAF High Solids Silicone may need just one.

Understanding Maintenance Needs and Longevity

Maintaining a silicone roof coating is essential. Addressing issues before they become problematic can help minimize the cost of repairs and maximize the service life of the coating.

As the roof flexes over time, issues with the seams might develop. A good rule of thumb is to get a roof inspected every six months. La aplicación de un sellador de silicona es una solución posible para áreas con fugas o grietas. Silicone sealant is UV stable and doesn't require a top coat, according to Soder.

Adding Silicone Roof Coatings to Your Toolbox

With many benefits, silicone roof coatings should be front of mind when planning roof restoration projects. Además, con la amplia variedad de opciones disponibles, es posible elegir el mejor tipo para cada techo. ¿Tienes más preguntas sobre los revestimientos para techos? GAF technical service reps are more than happy to assist you on your next coating project.