Cuando una parte del techo de tu edificio tiene una sección plana cubierta con un material tradicional para techos de pendiente baja (como TPO (Thermoplastic Polyolefin) membrane-una sola capa o membrana de betún modificado) y otra parte tiene una pendiente escarpada y está cubierta con tejas asfálticas, lo denominamos "techo mixto".

Un techo mixto puede ofrecer una bella apariencia estética, pero también puede traer aparejados desafíos únicos a la hora de evitar que el agua se filtre al edificio. Esto es lo que se debe tener en cuenta.

Los detalles son importantes

El punto en el que dos tecnologías diferentes de techo convergen suele requerir especial atención, opina Tim Rink, gerente de territorio de GAF. "El área en la que se une un techo de pendiente escarpada con uno de pendiente baja es donde pueden manifestarse posibles problemas", agrega. "La mayoría de los propietarios de edificios no piensan en eso ni tampoco en los problemas que pudieran surgir en los puntos de transición, en especial cuando se usan materiales para techos de dos fabricantes diferentes".

Si el techo mixto de tu edificio tiene material de dos fabricantes diferentes y en el punto de transición tienes una gotera, puede ser difícil encontrar la causa de dicha gotera. Además, la situación puede derivar en un desligue de responsabilidad, ya que los fabricantes optan por echarse la culpa mutuamente, observa Rink. Esto puede demorar las reparaciones y generar frustración en el propietario.

Protección sin complicaciones

Cuando eliges materiales del mismo fabricante, evitas todos estos problemas. GAF fabrica materiales tanto para techos de pendiente escarpada como para los de pendiente baja, los cuales pueden diseñarse para acoplarse a la perfección en los puntos de transición.

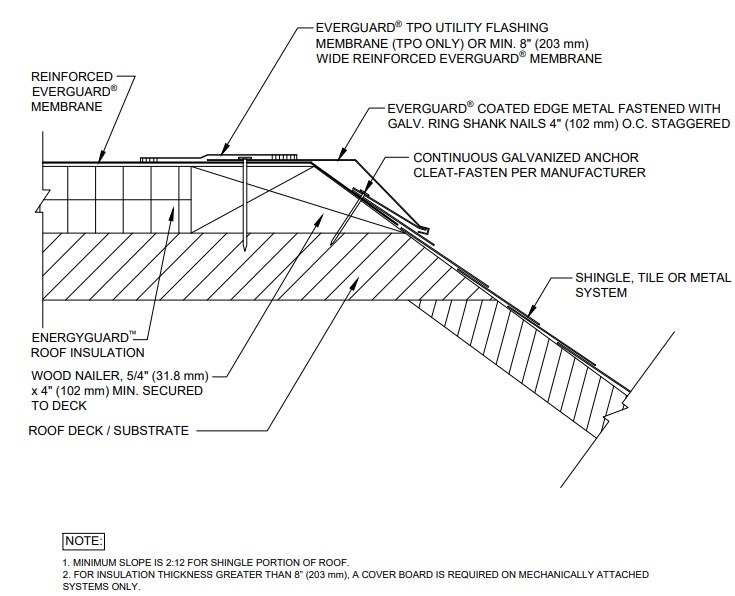

"Tenemos en AutoCAD® los detalles específicos de estos puntos de transición, independientemente de si el techo de pendiente baja tiene TPO (Thermoplastic Polyolefin) membrane-una sola capa o membrana de betún modificado", explica Rink. "Hay una manera concreta de instalar estos materiales para evitar estos problemas en los puntos de transición". Se puede ver un ejemplo concreto en lo que se detalla a continuación:

Muchos contratistas Master Elite y Master Select de GAF* están capacitados para implementar los métodos correctos de instalación de los materiales en un edificio con techo mixto. También deben cumplir con estrictos requisitos antes de obtener su certificación. Por ejemplo, deben tener las debidas licencias en su estado (si son obligatorias), tener la cobertura de seguro correcta, recibir capacitación de GAF y contar con una buena reputación en su comunidad.

Además de emitir la garantía, un inspector de campo de GAF hará una inspección visual de la instalación, incluyendo la revisión de los puntos de transición. Una vez que el techo pase la inspección, la garantía para las secciones del techo plana y de pendiente escarpada se emitirá en un solo documento en lugar de emitir varios documentos.

"Nuestra garantía para techos Diamond Pledge con el Apéndice de pendiente escarpada es una garantía NDL (sin límite monetario) que ofrece una cobertura todo en uno para el techo plano y las tejas que se colocan sobre él", explica Rink. "Si hay algún problema con el techo, solo se debe llamar por teléfono a fin de recibir una solución rápida y sencilla para un posible inconveniente de goteras, sin necesidad de responsabilizar a nadie".

Cómo extender la vida útil del techo con mantenimiento

Rink indica que hay opciones para los propietarios de edificios que realizan servicio y mantenimiento en sus techos mixtos para extender posiblemente la vida útil de dichos techos. "Hay incentivos por mantenimiento que pueden extender la garantía del techo si el propietario lleva a cabo un mantenimiento anual. A un techo de 20 años se le podría extender su vida útil por cinco años más si se le hiciera un buen mantenimiento**".

Cuando llega el momento de reemplazar el techo mixto de tu edificio, recuerda este dato clave: usar materiales de un único fabricante para las secciones del techo de pendiente baja y pendiente escarpada puede ofrecer mayor protección y representar menos problemas para los propietarios de edificios que usar materiales de diferentes fabricantes.

Tener un techo mixto no significa que debas tener diferentes fabricantes. Si deseas obtener más información u asesoramiento sobre tu techo mixto, haz clic aquí para comunicarte con alguien que pueda asistirte.

*Los contratistas inscritos en los programas de certificación de GAF no son empleados ni agentes de GAF, y GAF no controla ni supervisa de otro modo estas empresas independientes. Los contratistas pueden recibir beneficios, como puntos y descuentos de recompensa por lealtad en herramientas de comercialización de GAF por participar en el programa y ofrecer a GAF garantías mejoradas, que requieren el uso de una cantidad mínima de productos de GAF.

**Consulta el apéndice de extensión de garantía WellRoof de la Garantía de techos sin límite monetario Diamond Pledge si deseas conocer los detalles de la cobertura y las restricciones.